Offsite construction solutions

PANELISED

Steel

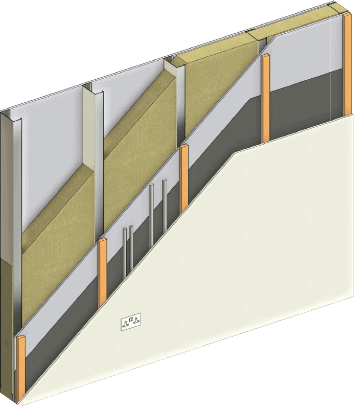

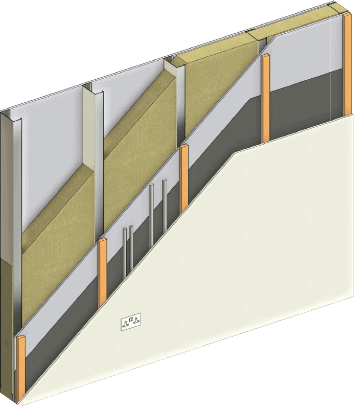

The simplicity of a structural panel, and the completeness of a flat packed volumetric wall helping address the conflicting challenges of embodied carbon, airtightness, acoustics, thermal and combustibility.

Timber

Our structural, closed panel timber system offers the lowest embodied carbon credentials whilst still maintaining high performance throughout.

Bespoke

Utilising timber and light steel panels, with roof and floor solutions in steel, concrete and timber, we can help you with a flexible, kit of parts solution to meet the exacting needs of the project and building demands, making us totally unique.

High performance without compromise!

With more emphasis on building performance and reducing our carbon impact in construction, it’s time you had the flexible solutions you need!

Full structural solution

Using a ‘kit of parts’ approach we can use different panel types for different compliance needs throughout your entire project.

Using a variety of light gauge steel or timber internal and external panels, non loadbearing walls, roof options and floor cassettes we can deliver full structure solutions to suit your exacting needs.

Envelope wrap solution

A simple system to ‘wrap around’ your concrete or steel framed building to ensure you maximise all the advantages of the panelised system.

Available in a range of substrates, our panels are unrivalled in every area of performance and allow you to accelerate your build programme and reduce your carbon impact without compromise.

X-Guard fire performance panels

The most robust balanced approach to combustibility and zero carbon with a structural solution in timber or steel.

Providing the simplicity of a structural panelised product, and the completeness of a flat packed volumetric wall helping address the conflicting challenges of airtightness, thermal, combustibility, embodied carbon and acoustics.

Why does it matter?

Reduce the

Performance gap

The performance gap in new building construction can lead to buildings that fail to meet energy efficiency, thermal comfort, and indoor air quality standards. As performance demands grow, the removal of the performance gap goes hand in hand with our DFMA process, futureproofing the building for the end client.

Improved

Sustainability

Reducing carbon emissions in the construction industry is a top priority and it’s imperative that we understand more about improving sustainability in areas such as embodied carbon, operational carbon, material tracability, environmental impacts and whole life carbon to provide a sustainable future for generation’s and the health of our planet.

Reduce your impact on site and

Accelerate delivery

The urgency to deliver new schools, homes, and hospitals has reached a crisis point in the industry. By utilising our solutions that offer flexibility across all sectors without compromising on performance factors, construction projects can be completed in a significantly shorter time-frame. This approach accelerates delivery, reduces time spent on-site, minimises environmental and local area impact, and streamlines project delivery processes.

Exceed building performance

Specifications

Building performance specification demands are growing along with environmental responsibilities so it’s crucial that we design our buildings to not only meet but exceed current specifications to ensure our buildings are futureproofed in areas such as thermal, acoustics, fire, robustness and air-tightness.

Lead the way in construction

Striking a balance between combustibility and zero carbon

- Timber

- Light guage steel

- Fire tested

- Large format

- Thermal performance

- Air permeability

- Insulation

- Flexibility

A structural closed panel timber system, with the lowest embodied carbon

Both the Timber and Steel panels’ product stages and construction processes have been assessed based on the raw material extraction and processing, manufacturer distances and an average distance to site based on our last 3 years of projects. From this early data collection the following are the results of the Product Carbon simulation carried out to calculate the embodied carbon of our Timber panels.

961kg CO2e

A structural closed panel Light Gauge Steel system, with the lowest embodied carbon

Both the Timber and Steel panels’ product stages and construction processes have been assessed based on the raw material extraction and processing, manufacturer distances and an average distance to site based on our last 3 years of projects. From this early data collection the following are the results of the Product Carbon simulation carried out to calculate the embodied carbon of our Timber panels.

1,324kg CO2e

Tested build ups for 60mins and 90mins for inside out and outside in.

Timber external wall panel is sheathed both sides with A rated boards which also achieve high levels of racking resistance and pull out test data. In tests the buildup exceeds 60 min outside in and inside out.

Steel external wall panels tested build ups for 60mins and 90mins for inside out and outside in.

Contact us for more details on our unrivalled fire certification collection

7m large format panels up to 3.45m wide and 7m long

Thermal performance range 0.2 – 0.11 W/m2k

Achievable by reducing the performance gap, eliminating any trades cutting on site, we engineer 'Letter box' openings in the factory which are lined with fire-tested non-combustible boards and allow for the safe passage of services without compromising the integrity of the thermal performance.

Air permeability down to 1 m3/hr air loss at a pressure of 50Pa

Achievable by reducing the performance gap, eliminating any trades cutting on site, we engineer 'Letter box' openings in the factory which are lined with fire-tested non-combustible boards and allow for the safe passage of services without compromising the integrity of the air permeability performance.

Thermal insulation is non combustible mineral wool in-line with fire testing

Closed panel systems provide improved thermal and acoustic insulation, leading to energy-efficient buildings that promote occupant comfort and reduced energy consumption.

Flexible building components

• A range of roof cassettes in Steel and Timber, mono pitched and flat applications, or traditional truss frame.

• Floors as part of our structure in PC plank, Steel or Timber Cassette

• Structural and Internal walls in light Steel or Timber

• All designed, engineered, manufactured by NZP. Installed by NZB

Timber

A structural closed panel timber system, with the lowest embodied carbon

Both the Timber and Steel panels’ product stages and construction processes have been assessed based on the raw material extraction and processing, manufacturer distances and an average distance to site based on our last 3 years of projects. From this early data collection the following are the results of the Product Carbon simulation carried out to calculate the embodied carbon of our Timber panels.

961kg CO2e

Light guage steel

A structural closed panel Light Gauge Steel system, with the lowest embodied carbon

Both the Timber and Steel panels’ product stages and construction processes have been assessed based on the raw material extraction and processing, manufacturer distances and an average distance to site based on our last 3 years of projects. From this early data collection the following are the results of the Product Carbon simulation carried out to calculate the embodied carbon of our Timber panels.

1,324kg CO2e

Fire tested

Tested build ups for 60mins and 90mins for inside out and outside in.

Timber external wall panel is sheathed both sides with A rated boards which also achieve high levels of racking resistance and pull out test data. In tests the buildup exceeds 60 min outside in and inside out.

Steel external wall panels tested build ups for 60mins and 90mins for inside out and outside in.

Contact us for more details on our unrivalled fire certification collection

Large format

7m large format panels up to 3.45m wide and 7m long

Thermal performance

Thermal performance range 0.2 – 0.11 W/m2k

Achievable by reducing the performance gap, eliminating any trades cutting on site, we engineer 'Letter box' openings in the factory which are lined with fire-tested non-combustible boards and allow for the safe passage of services without compromising the integrity of the thermal performance.

Air permeability

Air permeability down to 1 m3/hr air loss at a pressure of 50Pa

Achievable by reducing the performance gap, eliminating any trades cutting on site, we engineer 'Letter box' openings in the factory which are lined with fire-tested non-combustible boards and allow for the safe passage of services without compromising the integrity of the air permeability performance.

Insulation

Thermal insulation is non combustible mineral wool in-line with fire testing

Closed panel systems provide improved thermal and acoustic insulation, leading to energy-efficient buildings that promote occupant comfort and reduced energy consumption.

Flexibility

Flexible building components

• A range of roof cassettes in Steel and Timber, mono pitched and flat applications, or traditional truss frame.

• Floors as part of our structure in PC plank, Steel or Timber Cassette

• Structural and Internal walls in light Steel or Timber

• All designed, engineered, manufactured by NZP. Installed by NZB