Net Zero Panels making fire safety a priority.

Fire safety in buildings has always been a priority for main contractors, insurers, clients, design teams and suppliers alike, but since the Grenfell tragedy, it has become a key area of public concern too.

The tragedy led to changes to the Building Safety Act alongside updates to legislation including the Joint Code of Practice, meaning that when it comes to delivering projects, it’s now more critical than ever to sub-contract to accredited partners you can trust.

Our fabric-first approach combines the best sustainable technology with the highest levels of compliance. We have a proven track record of delivering fast, safe solutions that reduce the embodied carbon of a build by half and improve its overall operational carbon performance.

By focusing on what we call the Four Cs – cost, carbon, compliance and combustibility – we manufacture and test panels that help main contractors to deliver safe, sustainable buildings that will stand the test of time.

But how?

Image: Multi-story building by Net Zerto Panels

Combining compliance with market-leading innovation

We want to make things easy for main contractors, which means compliance and fire safety are our highest priorities. We take a ‘challenge-led’ approach, considering potential issues to find innovative solutions before the first panel arrives on your site.

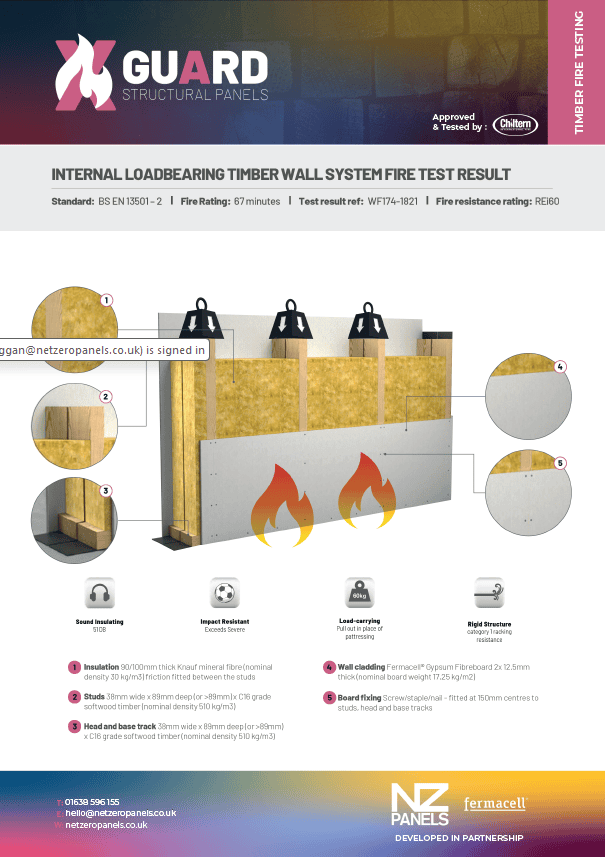

When it comes to fire safety, our strong partnerships with compliance market leaders, such as Fermacell and Rockwool, ensure that all of our panels meet and exceed compliance expectations.

For instance, we work closely with our material partners which conduct testing on panels and structural elements: providing a comprehensive level of certification for our products which is not offered by other companies.

Image: Example of one of the NZP’s Fire testing documents, developed in partnership with Fermacell.

Equally, our fabric-first approach ensures that our materials are rigorously tested not just on thermal ability, but the combination of materials which effect the combustible performance. In a modern construction industry we insist on a holistic approach in order to guarantee buildings stand up to intense future scrutiny.

Driving safety and sustainability with X-Guard

To ensure high levels of quality control, we engineer, manufacture and safely install solutions across the UK from our specialist factory in Cambridge; providing agile, adaptable solutions – whether that is a full structural solution, an envelope wrap of our innovative X-Guard solution.

Our X-Guard solution takes compliance and high performance to the next level. This panel solution is designed and stringently tested to ensure trust and fast installation in line with project deadlines.

Using recycled materials and materials that can go on to be recycled, along with our manufacturing process that is designed to eliminate waste, we are able to measure the embodied carbon in our buildings and ensure that they meet the highest eco-standards.

With a 60-year design life and the ability to be recycled at end of life, unlike structural insulated panels (SIP), our X-Guard solution combines the best in compliance, testing and sustainability.

Compliance across sectors

We have partnered with main contractors for years across multiple sectors from education to healthcare, doing our part to drive the highest levels of compliance across projects.

Want to speak to our compliance experts? Get in touch.